Drone Battery Storage, Transport, and Discharge

Proper storage, transport, and discharge procedures are critical aspects of drone battery management that directly impact safety and battery lifespan. After years of experience managing hundreds of LiPo, LiHV, and Li-ion batteries, I've learned that these often-overlooked aspects of battery care can make the difference between batteries that last for years and those that fail prematurely—or worse, create safety hazards. This comprehensive guide covers everything I've learned about safely storing and transporting lithium batteries, as well as proper discharge techniques and fireproof containment solutions.

Introduction to Battery Storage

Lithium-based batteries present unique safety challenges when not in use or during transport. Understanding proper handling procedures is essential for all drone operators, from hobbyists to professionals.

The Importance of Proper Battery Management

Correct storage, transport, and discharge practices are vital for several reasons:

- Safety: Lithium batteries can pose significant fire hazards if mishandled

- Battery Longevity: Proper storage extends the useful life of expensive batteries

- Performance Preservation: Correct procedures maintain battery capacity and performance

- Regulatory Compliance: Transport regulations for lithium batteries are strictly enforced

- Environmental Responsibility: Proper handling reduces environmental impact

I learned the importance of proper battery management the hard way. Early in my drone journey, I stored several fully charged batteries in a drawer for a few months over winter. When spring arrived, most had significantly reduced capacity, and two had developed dangerous cell imbalances. That mistake cost me over $200 in ruined batteries and taught me to take storage procedures seriously.

Understanding Battery Risks

Lithium batteries contain significant energy in a compact package, creating inherent risks:

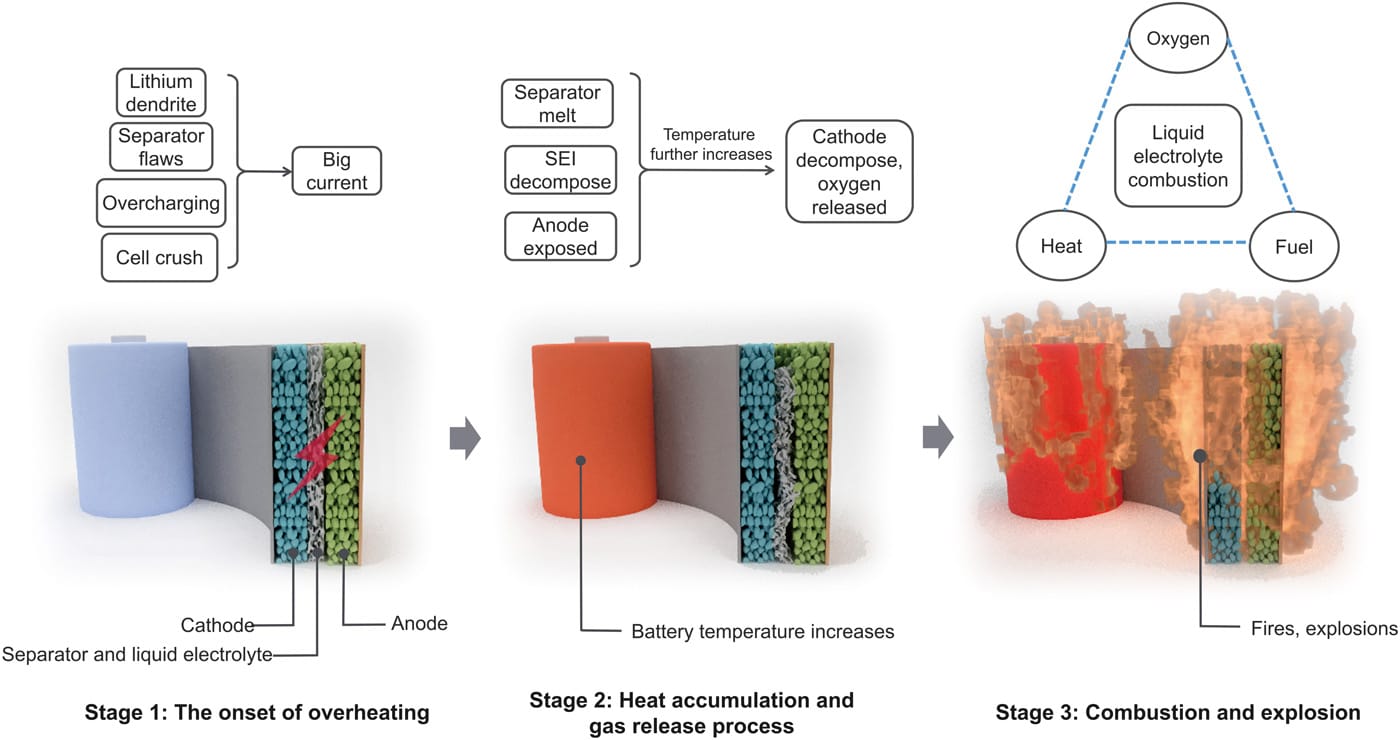

Fire and Thermal Runaway

- Thermal Runaway: Self-accelerating, exothermic chemical reaction

- Causes: Physical damage, overcharging, over-discharging, excessive heat

- Progression: Cell venting → smoke → fire → adjacent cell involvement

- Temperature: Can exceed 1000°C

- Suppression Challenges: Self-oxidizing, difficult to extinguish

I've witnessed a thermal runaway event at a drone racing competition when a pilot's crashed battery was improperly handled. What started as a small amount of smoke quickly escalated to intense flames that melted part of the plastic bleachers.

Chemical Hazards

- Electrolyte: Contains flammable and toxic compounds

- Venting Gases: Hydrogen fluoride and other toxic substances

- Exposure Risks: Respiratory irritation, chemical burns, long-term health effects

- Environmental Impact: Soil and water contamination

After a minor incident where I got electrolyte on my hands from a damaged battery, I now keep nitrile gloves in my field kit. The burning sensation from battery electrolyte is not something you want to experience—it took hours of flushing with water to fully relieve the irritation.

Electrical Hazards

- Short Circuits: Can cause immediate thermal events

- High Current Capability: Even partially charged batteries can deliver dangerous currents

- Connector Risks: Exposed terminals can contact metal objects

- Parallel Configurations: Increased energy and current capability

I once so a video of someone shorting a battery with metal tool. The instantaneous current melted part of the tool and caused the battery to vent. Now, I am pretty religious about using silicon caps on battery terminals during transport and storage.

Understanding these risks has shaped my approach to battery management. I don't view safety measures as optional extras but as essential practices that protect my investment, my property, and potentially my life.

Battery Storage

Optimal Storage Conditions

Storage Voltage

- LiPo/Li-ion: 3.8-3.85V per cell (approximately 50% charged)

- LiHV: 3.85-3.9V per cell (approximately 50% charged)

- NiMH: 40-60% charged

The storage voltage is perhaps the single most important factor in battery longevity. I've conducted my own long-term tests with identical batteries stored at different voltages. After six months, the batteries stored at proper storage voltage retained over 95% of their capacity, while those stored fully charged lost 15-30% of their capacity permanently. For expensive high-capacity batteries, this difference can represent significant savings over time.

For more detailed information on battery chemistry, see:

Overview of Drone Battery Types and Chemistry

Temperature Considerations

- Ideal Range: 5-20°C

- Avoid Extremes: Both high and low temperatures accelerate degradation

- Humidity Control: 45-65% relative humidity ideal

- Temperature Stability: Avoid frequent or rapid temperature changes

I store my batteries in area in my basement, where the temperature stays around 15°C year-round. For pilots without temperature-controlled options, I recommend at least keeping batteries out of attics, garages, or other spaces with extreme temperature fluctuations.

Location Requirements

- Away from Direct Sunlight: UV exposure degrades battery materials

- Away from Heat Sources: Heating vents, electronics, direct sunlight

- Well-Ventilated Area: Allows dissipation of any gases if venting occurs

- Away from Combustibles: Minimum 1 meter clearance from flammable materials

- Away from Children and Pets: Prevent accidental damage or exposure

My battery storage area follows all these guidelines, with the added precaution of being near a concrete floor and away from any important documents or valuables. I've seen too many stories of battery fires destroying homes to take unnecessary risks.

Storage Containers and Solutions

Fireproof Storage Options

- LiPo Safe Bags:

- Construction: Fiberglass or similar fire-resistant material

- Protection Level: Moderate; contains small fires and limits spread

- Capacity: Available in various sizes from single battery to multi-battery

- Cost: Low to moderate ($10-30)

- Limitations: Not completely fireproof, primarily delays fire propagation

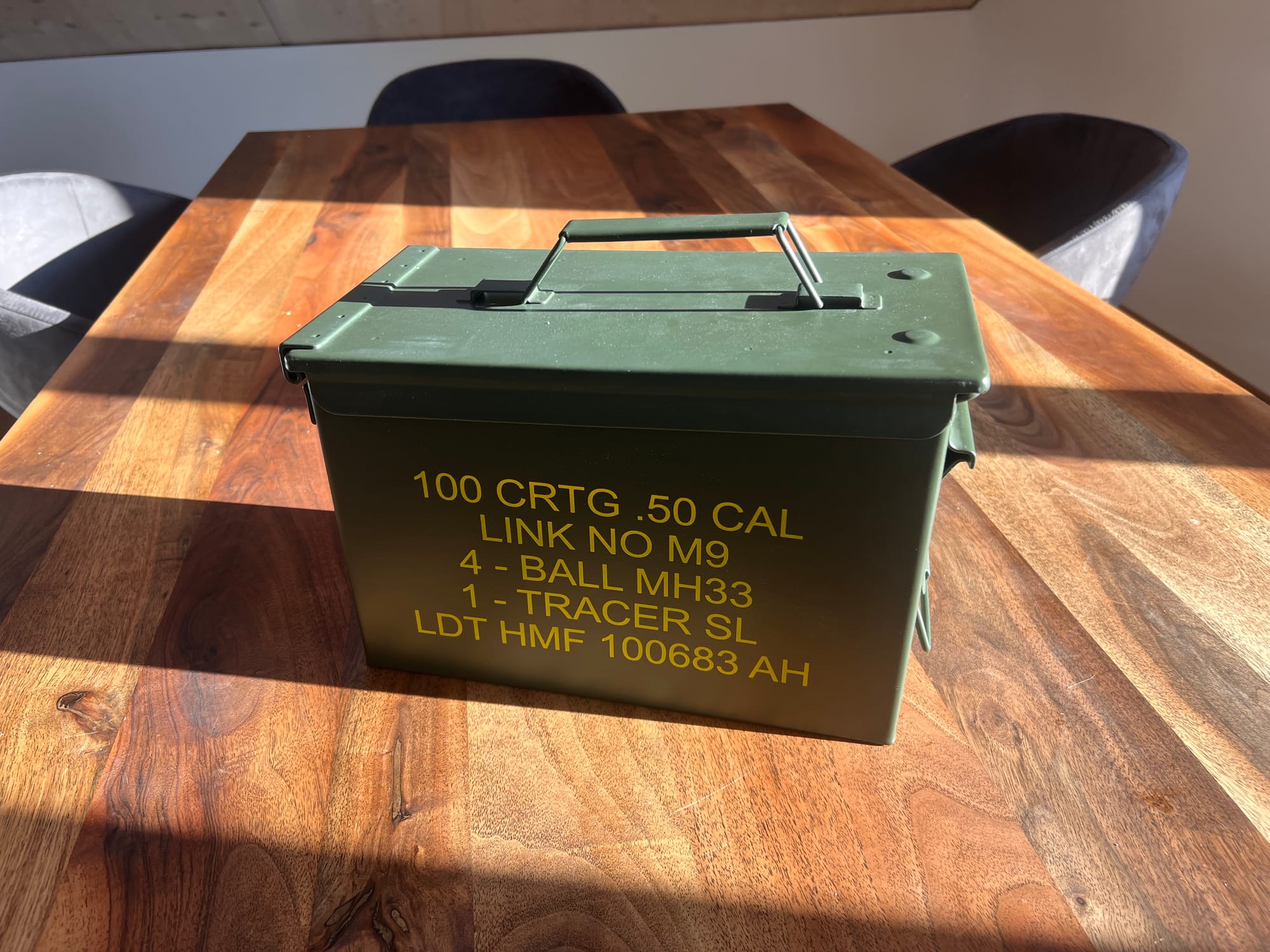

- Ammo Cans:

- Construction: Steel with seal modification (vent hole required)

- Protection Level: Good; contains fires but can build pressure

- Capacity: Multiple batteries depending on size

- Cost: Moderate ($20-40)

- Limitations: Requires modification, can become projectile if sealed

- LiPo Bunkers/Safes:

- Construction: Metal with fire-resistant lining

- Protection Level: Excellent; specifically designed for battery fires

- Capacity: Various sizes available

- Cost: Moderate to high ($50-300)

- Limitations: Bulkier, less portable than other options

- Ceramic/Metal Containers:

- Construction: Ceramic flower pots, metal toolboxes with modifications

- Protection Level: Moderate to good depending on design

- Capacity: Varies by container

- Cost: Low to moderate ($10-50)

- Limitations: DIY solutions require proper setup and testing

For my home storage, I use a modified ammo box with ceramic tile lining at the bottom and the rubber seal removed to prevent pressure buildup in the event of fire. For travel, I use LiPo safe bags inside a metal toolbox. The layered approach provides redundant protection - you definitely want to avoid the need of firefighting when driving on autobahn.

Commercial Storage Solutions

- BAT-SAFE:

- Features: Thermal protection, filtered venting, carrying handle

- Capacity: Multiple batteries depending on model

- Advantages: Purpose-built, tested for battery fires

- Price Range: $60-150

- LIPO SACK:

- Features: Lightweight, portable, various sizes

- Capacity: 1-10 batteries depending on model

- Advantages: Convenient for field use, good for transport

- Price Range: $15-40

- LIPO VAULT:

- Features: Hard case, fire-resistant materials, secure closure

- Capacity: Multiple batteries in organized compartments

- Advantages: Durable, good organization, high protection

- Price Range: $40-100

- BATSAFE:

- Features: Steel construction, thermal lining, venting system

- Capacity: Large multi-battery capacity

- Advantages: High protection level, professional grade

- Price Range: $100-300

After testing several commercial options, I've found the BAT-SAFE to offer the best balance of protection, capacity, and price for serious hobbyists. The filtered venting system is particularly impressive—it allows gases to escape while containing flames and most smoke.

DIY Storage Solutions

- Modified Ammo Can:

- Materials: Metal ammunition can, high-temp silicone, vent hole

- Construction: Remove rubber seal, drill vent hole, line with ceramic tile

- Effectiveness: Good containment if properly modified

- Cost: $20-30 plus modifications

- Ceramic Pot System:

- Materials: Ceramic flower pot, ceramic tile, sand

- Construction: Layer of sand, batteries, covering pot

- Effectiveness: Good thermal insulation and containment

- Cost: $15-25

- Cinder Block Storage:

- Materials: Cinder blocks, ceramic tile, metal cover

- Construction: Arrange blocks, line with ceramic, cover with metal

- Effectiveness: Excellent thermal mass and containment

- Cost: $10-20

- Fire Brick Enclosure:

- Materials: Fire bricks, fire-resistant mortar

- Construction: Construct box with bricks, include vent

- Effectiveness: Very high heat resistance

- Cost: $30-50

My first home storage solution was a modified ammo can, and I still use it today. The key modification is removing the rubber seal to prevent pressure buildup in the event of fire. Without this adjustment, the can could potentially rupture explosively. I also line the bottom with ceramic tiles to provide thermal insulation.

Long-Term Storage Procedures

Preparation for Long-Term Storage

- Inspection: Check for damage, swelling, or other issues

- Voltage Verification: Confirm proper storage voltage (3.8-3.85V per cell)

- Balance Check: Ensure cells are balanced within 0.01-0.03V

- Connector Protection: Secure balance leads, insulate main connectors

- Documentation: Label with date of storage and condition

Before storing any battery long-term, I perform a thorough health check. Any battery showing signs of damage or significant imbalance gets set aside for disposal rather than storage. I've found that problems only worsen during storage, so it's not worth keeping questionable batteries.

Maintenance During Storage

- Regular Checks: Monthly visual inspection

- Voltage Monitoring: Check voltage every 2-3 months

- Rotation: Consider cycling batteries every 3-6 months

- Environment Verification: Ensure storage conditions remain optimal

- Rebalancing: Return to storage voltage if significant drift occurs

I set calendar reminders to check my stored batteries every three months. This simple habit has helped me catch several batteries that were self-discharging abnormally, allowing me to address issues before they became serious problems.

Returning to Service After Storage

- Pre-Use Inspection: Thorough visual check for issues

- Voltage Verification: Confirm voltage hasn't dropped below safe levels

- Initial Charge: Perform full balance charge at reduced rate (0.5C)

- Capacity Test: Consider testing capacity after extended storage

- Performance Monitoring: Watch for abnormal behavior during first few uses

After long-term storage, I treat batteries almost like they're new again. The first charge is always done at a reduced rate (0.5C) with careful monitoring. I've found this gentle approach helps batteries recover from storage and provides an early warning if there are any issues.

Battery Transport

Domestic Transport Considerations

Car/Road Transport

- Containment: Always use LiPo safe bag or fire-resistant container

- Temperature Control: Avoid leaving batteries in hot vehicles

- Secure Positioning: Prevent movement and potential damage

- Accessibility: Keep in easily accessible location in case of emergency

- Ventilation: Ensure some airflow around battery containers

I transport batteries in my vehicle every week, and I've developed a system that balances safety and convenience. I use LiPo safe bags inside a metal toolbox, positioned where I can quickly access them if needed. On hot days, I take the extra precaution of bringing the batteries with me rather than leaving them in the vehicle, where temperatures can easily exceed safe limits.

Air Travel (Carry-On)

- State Regulations:

- Must be carried in cabin baggage, not checked

- Limited to 100Wh per battery (larger batteries may require approval)

- Terminals must be protected against short circuits

- Usually limited to 20 spare batteries per passenger

- Airline-Specific Rules:

- Some airlines have stricter policies

- May require declaration at check-in

- Some may require batteries to be in original packaging

- Capacity documentation may be required

- Preparation:

- Discharge to storage voltage (30-50%)

- Individual protection (terminal tape, battery cases)

- Proper documentation of capacity (label with Wh)

- Organized for easy inspection

I travel frequently with drone batteries, and proper preparation is essential. I've had my batteries inspected by airport security numerous times, and having them neatly organised with protected terminals and clear capacity labelling has always resulted in smooth screenings.

Shipping by Mail/Courier

- Domestic Shipping Regulations:

- Classified as Class 9 Hazardous Materials

- Requires proper declaration and labeling

- May require certified packaging

- Some carriers restrict or prohibit lithium battery shipments

- Preparation Requirements:

- Discharge to 30% or less of capacity

- Individual battery protection

- Inner packaging to prevent movement

- Outer packaging meeting specific standards

- Proper hazard labels and documentation

Shipping batteries commercially requires compliance with hazardous materials regulations. For most hobbyists, I recommend using specialized battery shipping services rather than attempting to navigate the complex regulations independently.

International Transport Regulations

IATA Dangerous Goods Regulations

- Classification: UN3480 (batteries alone) or UN3481 (with equipment)

- State of Charge: Maximum 30% for air transport

- Packaging Requirements:

- UN specification packaging for batteries alone

- Strong outer packaging for batteries with equipment

- Protection against short circuit and activation

- Documentation:

- Shipper's Declaration for Dangerous Goods

- Air Waybill with handling information

- May require Dangerous Goods certification to prepare

International battery transport is even more strictly regulated than domestic. When traveling internationally with drone equipment, I always research the specific requirements for both my destination country and any countries I'll be transiting through. Some countries have additional restrictions beyond the standard IATA regulations.

Customs Considerations

- Import/Export Restrictions: Some countries restrict lithium battery imports

- Documentation Requirements: Technical specifications, safety certifications

- Taxation: May be subject to special duties or taxes

- Carrier Limitations: Not all carriers accept international battery shipments

I once had batteries confiscated at customs in a country that had recently implemented stricter lithium battery import regulations. Since then, I always verify the current regulations for my destination before traveling and carry appropriate documentation showing compliance.

Emergency Procedures During Transport

Signs of Battery Problems

- Visual Indicators:

- Swelling or puffing

- Leaking or unusual odor

- Excessive heat

- Smoke or visible damage

- Response Actions:

- Stop vehicle in safe location

- Turn off HVAC/ventilation

- Remove battery to non-flammable surface if safe

- Use appropriate fire extinguisher if fire occurs

- Evacuate if significant smoke or fire

I keep a small spray fire extinguisher in my vehicle specifically for battery emergencies. I've also practiced my response to a battery issue while driving, so I can react quickly and safely if a problem occurs.

Vehicle Fire Containment

- Preparation:

- A suitable fire extinguisher accessible

- Thermal containment bag for emergency use

- Heat-resistant gloves

- Emergency contact information

- Response Plan:

- Safe pullover procedure

- Battery isolation method

- Extinguisher use protocol

- Evacuation criteria

- Emergency services contact

Having a clear plan for battery emergencies during transport provides peace of mind. I've never had to implement my emergency plan, but knowing it's there allows me to transport batteries with confidence.

Battery Discharge

Purpose of Discharge

Storage Preparation

- Optimal Storage Voltage: Discharge to 3.8-3.85V per cell

- Benefits: Reduces chemical degradation, extends lifespan

- Application: Any battery not being used within 48 hours

- Importance: Can double or triple battery lifespan compared to storing fully charged

Proper storage discharge is one of the most impactful practices for extending battery life. I've seen dramatic differences in longevity between batteries that were consistently stored at proper voltage versus those that were left fully charged between uses.

End-of-Life Discharge

- Safe Disposal Preparation: Complete discharge before recycling

- Procedure: Specialized slow discharge to 0V

- Purpose: Eliminates energy content for safe handling

- Requirements: Specific discharge equipment for full depletion

Before disposing of any lithium battery, I completely discharge it using a specialized discharge tool that can bring the voltage to zero. This extra step significantly reduces the fire risk during transport to recycling facilities.

Performance Testing

- Capacity Verification: Controlled discharge to measure actual capacity

- Internal Resistance Testing: Discharge testing to assess battery health

- Cycle Testing: Repeated charge/discharge to evaluate longevity

- Application: Evaluating new batteries or assessing aging batteries

I periodically test my batteries' capacity through controlled discharge tests. This practice helps me track degradation over time and make informed decisions about when to retire batteries before they become safety risks.

For more detailed information on battery performance testing, see:

Battery Health Analysis

Discharge Methods

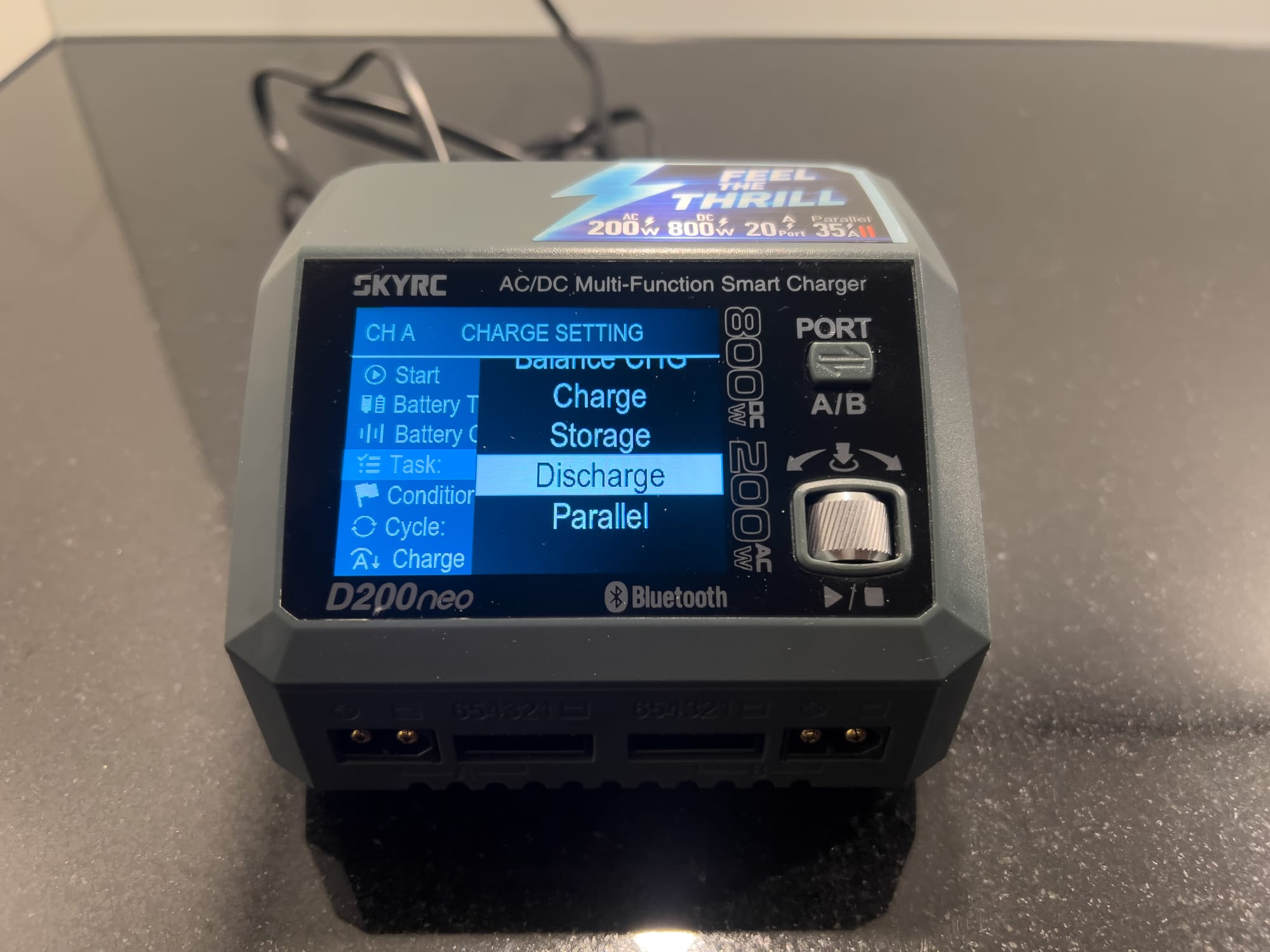

Controlled Discharge

- Charger Discharge Function:

- Many chargers include storage discharge mode

- Typically limited to 1C or lower discharge rate

- Stops automatically at target voltage

- Balances cells during process

- Dedicated Discharge Tools:

- Purpose-built for battery discharge

- Often include resistive loads and cooling

- May offer data logging capabilities

- Range from simple to sophisticated

- Load Banks:

- Professional equipment for precise discharge

- Constant current or constant resistance options

- Often include cooling and safety features

- Used for testing and maintenance

My primary discharge method is my charger's storage function, which conveniently brings batteries to the optimal storage voltage. For capacity testing, I use a dedicated discharge tool that provides more precise measurements and data logging.

Field Discharge Techniques

- Hover Discharge:

- Flying drone in hover until reaching storage voltage

- Requires voltage monitoring

- Inefficient but convenient

- Risk of over-discharge if not monitored

- Low-Power Flying:

- Gentle flying to reduce battery voltage

- More enjoyable than simple hovering

- Requires voltage monitoring

- Avoid aggressive maneuvers near end of discharge

- Discharge Plugs/Resistors:

- Simple resistive loads that connect to battery

- Available in various resistances for different discharge rates

- Require monitoring to prevent over-discharge

- Generate heat during use

- Storage Discharge Function on Field Chargers:

- Many field chargers include storage function

- Convenient when charging facilities available

- More precise than manual methods

- May be slow depending on charger capabilities

In the field, I often use gentle flying to bring batteries down to storage voltage. It's more enjoyable than hovering and puts less stress on the motors. I always monitor voltage with my OSD or telemetry system to avoid over-discharging.

Discharge Safety

Over-Discharge Prevention

- Minimum Safe Voltage:

- LiPo/Li-ion/LiHV: 3.0V per cell absolute minimum

- Recommended minimum: 3.5V per cell during use

- Storage target: 3.8-3.85V per cell

- Monitoring Methods:

- Flight controller low voltage warnings

- Battery voltage telemetry

- Visual voltage display

- Audible low voltage alarms

- Recovery Limitations:

- Cells below 2.5V may be permanently damaged

- Cells below 3.0V require special recovery procedures

- Repeated discharge below 3.2V reduces lifespan

I've configured my flight controller to provide progressive warnings as battery voltage decreases. My first warning comes at 3.7V per cell, giving me plenty of time to land before reaching critical levels. I've seen too many pilots push their batteries to the absolute limit, significantly reducing their lifespan for a few extra seconds of flight time.

Heat Management During Discharge

- Temperature Monitoring:

- Maximum safe temperature: 60°C

- Optimal discharge temperature: 15-35°C

- Cooling periods for extended discharge

- Cooling Considerations:

- Airflow requirements

- Heat sink options

- Discharge rate reduction

- Thermal monitoring

- Warning Signs:

- Battery too hot to touch comfortably

- Swelling during discharge

- Unusual odors

- Voltage instability

Heat management is particularly important during high-current discharges. When using discharge tools, I always ensure adequate airflow and monitor temperature regularly. If a battery becomes uncomfortably warm to touch, I immediately reduce the discharge rate or pause the process to allow cooling.

Battery Management Systems

Inventory Management

- Battery Tracking:

- Unique identification (numbering/labeling)

- Purchase date documentation

- Cycle count tracking

- Performance history

- Categorization Systems:

- By capacity and cell count

- By age and condition

- By application (racing, freestyle, long-range)

- By chemistry (LiPo, LiHV, Li-ion)

- Rotation Strategies:

- First in, first out usage

- Condition-based selection

- Application-specific assignment

- Balanced usage across inventory

I maintain a detailed inventory of all my batteries in a spreadsheet, tracking purchase date, cycle count, and performance notes. This system has helped me identify patterns in battery degradation and optimize my replacement schedule. For my racing drones, I use a colour-coded system: green stickers for newer batteries, yellow for middle-aged, and red for those nearing retirement.

Organization is key when managing multiple batteries. I've built custom storage racks with individual compartments for each battery, clearly labeled with capacity, cell count, and status. This system makes it easy to select the right batteries for each application and ensures none are forgotten in storage.

Digital Management Tools

RC E-Calc Pro

RC Flight and Battery Log

- Features to Look For:

- Cycle counting

- Performance tracking

- Maintenance reminders

- Storage status monitoring

- Integration Capabilities:

- Barcode/QR scanning

- Cloud synchronization

- Multiple device support

- Data export options

I use a combination of a custom spreadsheet and a mobile app to track my battery inventory. The app allows me to quickly scan QR codes on my batteries to log flights and update cycle counts while in the field, which then syncs to my main database when I return home.

Emergency Procedures and Safety

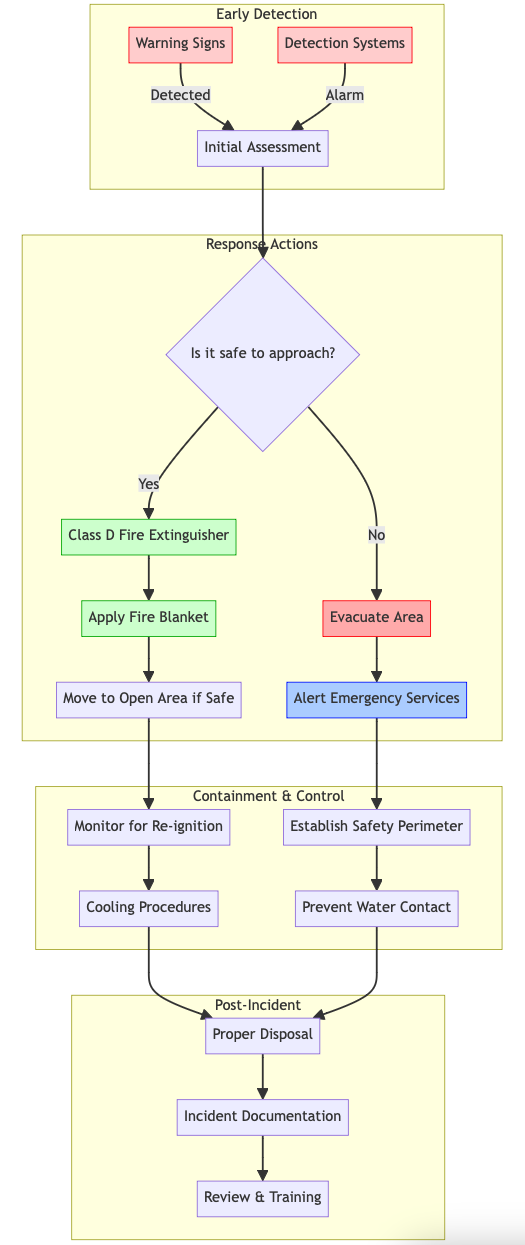

Fire Response Plan

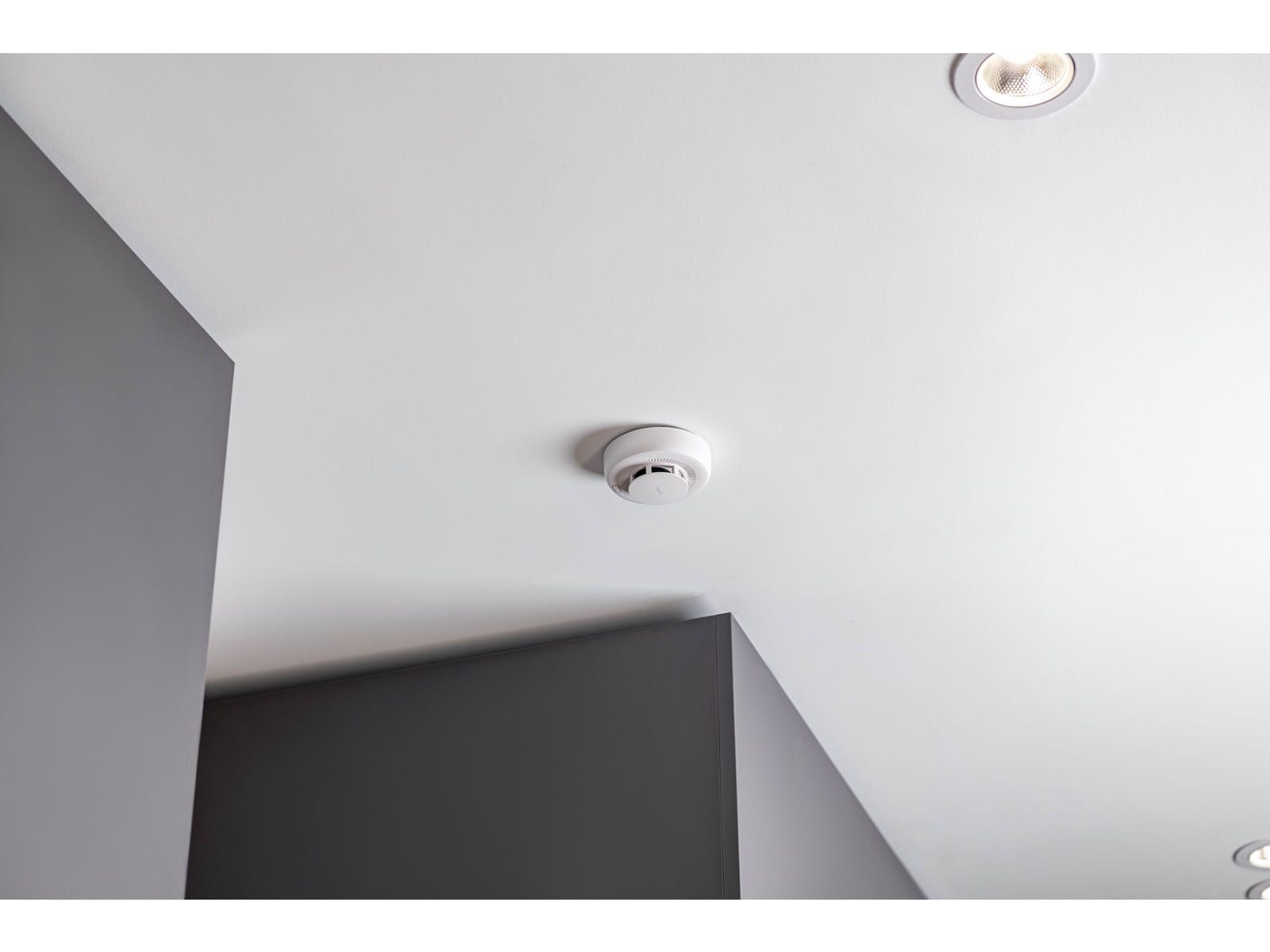

Early detection is critical for effective response to battery incidents. I've installed specialized smoke detectors near my battery storage and charging areas, and I perform regular visual inspections of all batteries. These simple measures have helped me catch potential issues before they escalated to emergencies.

Firefighting Approach

- Appropriate Extinguishers:

- A fire extinguisher suitable for batteries and electronics

- Dry sand

- LiPo fire-specific extinguishers

- Water (for surrounding materials only, not battery!)

- Extinguishing Technique:

- Maintain safe distance

- Apply extinguishing agent to base of fire

- Continue application after flames subside

- Be prepared for reignition

- When Not to Fight the Fire:

- Large battery involvement

- Rapid fire spread

- Toxic smoke accumulation

- Inadequate safety equipment

- Post-Fire Actions:

- Continue monitoring for reignition (24+ hours)

- Ventilate area thoroughly

- Document incident

- Proper disposal of damaged materials

I keep a suitable fire extinguisher within reach of my charging and storage areas. After witnessing a battery fire that reignited hours after it appeared to be extinguished, I now know that continued monitoring is essential—lithium battery fires can restart even when they appear to be out.

Evacuation Procedures

You must have a clearly posted evacuation plan near battery storage area, with primary and secondary routes marked. Everyone in your household / business facility must know the plan and understand the unique hazards of lithium battery fires, including the toxic smoke they produce.

Health and Environmental Considerations

Exposure Risks

- Inhalation Hazards:

- Hydrogen fluoride and other toxic gases

- Metal oxide particles

- Carbon monoxide

- Volatile organic compounds

- Skin/Eye Contact Risks:

- Electrolyte chemical burns

- Irritation from particulates

- Thermal burns from hot materials

- Corrosive compounds

- First Aid Measures:

- Fresh air for inhalation exposure

- Flush eyes/skin with water for 15+ minutes

- Do not induce vomiting if ingested

- Seek medical attention for all exposures

After a minor incident where I got electrolyte on my hands from a damaged battery, I now keep a first aid kit specifically for battery-related injuries in my work area. The burning sensation from battery electrolyte is not something you want to experience—it took hours of flushing with water to fully relieve the irritation.

Environmental Impact

- Contamination Concerns:

- Soil contamination from electrolyte

- Water pollution risk

- Air quality degradation

- Persistent toxic compounds

- Mitigation Approaches:

- Containment of fire residue

- Proper disposal through hazardous waste channels

- Professional cleanup for significant incidents

- Environmental monitoring if warranted

- Reporting Requirements:

- Local environmental agencies

- Fire department documentation

- Insurance notification

- Hazardous material incident reporting

I take environmental responsibility seriously when handling batteries. All my damaged or end-of-life batteries go to proper recycling facilities, and I have containment measures in place to prevent environmental contamination in case of leaks or fires.

FAQ: Common Questions About Battery Storage and Transport

How long can I store my drone batteries?

The storage duration for drone batteries depends on proper preparation and periodic maintenance:

Properly Prepared Batteries (at storage voltage, correct temperature):

- Short-term (1-3 months): No special maintenance needed beyond initial preparation

- Medium-term (3-12 months): Check voltage every 3 months, rebalance if needed

- Long-term (1-2 years): Check monthly, cycle every 6 months, expect some capacity loss

- Extended (2+ years): Not recommended, significant capacity loss likely

Maintenance Requirements by Duration:

- Monthly: Visual inspection for swelling or damage

- Quarterly: Voltage check, rebalance if needed

- Semi-annually: Full charge/discharge cycle, performance assessment

- Annually: Capacity testing, retirement evaluation

Capacity Loss Expectations:

- First year: 5-15% capacity loss with proper storage

- Second year: Additional 10-20% loss

- Third year+: Accelerating degradation, often 30%+ total loss

In my experience, even with perfect storage conditions, lithium batteries will degrade over time. I've found that batteries stored properly at storage voltage typically retain about 90% of their capacity after one year, while batteries stored fully charged might retain only 70-75%. For critical applications, I rotate my battery stock regularly and avoid storing batteries for longer than necessary.

What's the best container for storing multiple batteries?

The ideal storage container depends on your specific needs, battery quantity, and risk assessment:

For Small Collections (1-5 batteries):

- LiPo Safe Bag: Good balance of protection, cost, and convenience

- Advantages: Portable, affordable, widely available

- Limitations: Limited protection for catastrophic failures

- Cost: $15-30

- Best for: Casual users, travel, field storage

- Modified Ammo Can: Excellent protection-to-cost ratio

- Advantages: Durable, good containment, relatively portable

- Limitations: Requires proper modification (vent hole, seal removal)

- Cost: $20-40 plus modifications

- Best for: Home storage, workshop settings

For Medium Collections (5-20 batteries):

- Purpose-Built LiPo Safe: Best overall protection

- Advantages: Designed specifically for battery fires, filtered venting

- Limitations: Higher cost, less portable than bags

- Cost: $60-150

- Best for: Serious hobbyists, small commercial operations

- Fire-Resistant Cabinet: Organized storage with protection

- Advantages: Organized storage, good fire resistance, lockable

- Limitations: Not portable, higher cost

- Cost: $200-500

- Best for: Permanent installations, workshops

For Large Collections (20+ batteries):

- Professional Battery Storage System: Maximum protection and organization

- Advantages: Highest safety level, often includes monitoring

- Limitations: Very expensive, permanent installation

- Cost: $500-2000+

- Best for: Commercial operations, large inventories

I've used all these solutions at different stages of my drone journey. For my current setup, I use a combination of modified ammo cans for long-term storage and LiPo guard bags for daily travel. The layered approach provides redundant protection and convenient access to frequently used batteries.

Is it safe to transport batteries in my car?

Transporting lithium batteries in vehicles requires specific precautions:

Safety Considerations:

- Temperature Extremes: Vehicle interiors can reach 60°C+ in summer

- Impact Risks: Loose batteries can be damaged in sudden stops or accidents

- Confined Space: Limited ventilation and escape routes if fire occurs

- Proximity to Fuel: Vehicle contains flammable materials and fuel

Essential Precautions:

- Always use containment: LiPo safe bag minimum, metal container preferred

- Secure positioning: Prevent movement during driving

- Temperature management: Never leave batteries in hot vehicles

- Accessibility: Store where you can quickly remove them if needed

- Monitoring: Check batteries before and after transport

My Recommended Transport Procedure:

- Discharge to storage voltage (3.8V per cell)

- Place in appropriate fire-resistant container

- Secure container to prevent movement

- Keep away from direct sunlight

- Take batteries with you when leaving vehicle for extended periods

- Have a plan for emergency response

I transport batteries almost weekly and have developed a system that balances safety and convenience. I use LiPo safe bags inside a metal toolbox, positioned where I can quickly access them if needed. On hot days, I take the extra precaution of bringing the batteries with me rather than leaving them in the vehicle.

How do I prepare batteries for air travel?

Air travel with lithium batteries requires strict adherence to regulations and careful preparation:

Current Regulations (Always Check for Updates):

- Carry-on Only: Lithium batteries must be in carry-on baggage, never checked

- Capacity Limits:

- Under 100Wh: Generally allowed without approval

- 100-160Wh: Limited quantity (usually 2) with airline approval

- Over 160Wh: Typically prohibited on passenger aircraft

- Quantity Restrictions: Most airlines limit to 20 spare batteries per passenger

- Terminal Protection: All batteries must have protected terminals

Calculating Watt-Hours (Wh):

- Wh = Nominal Voltage × Capacity (Ah)

- Example: 3S 3000mAh LiPo = 11.1V × 3Ah = 33.3Wh

My Preparation Steps:

- Discharge to Safe Level: 30-50% charge (storage voltage)

- Terminal Protection:

- Cover main connectors with protective caps or tape

- Secure balance leads with tape or connector protectors

- Ensure no exposed metal contacts

- Individual Packaging:

- Place each battery in separate plastic bag or container

- Use LiPo safe bags for additional protection

- Documentation:

- Label each battery with capacity in Wh

- Bring manufacturer specifications if available

- Print relevant regulations

My Airport Security Tips:

- Declare batteries at security checkpoint

- Be prepared to show batteries for inspection

- Allow extra time for security screening

- Know airline-specific policies (some are stricter than regulations)

I travel frequently with drone batteries, and proper preparation is essential. I've had my batteries inspected by customs agents numerous times, and having them neatly organized with protected terminals and clear capacity labeling has always resulted in smooth screenings.

What's the safest way to dispose of damaged batteries?

Proper disposal of damaged lithium batteries is essential for safety and environmental protection:

When to Dispose:

- Physical damage (punctures, dents, crushed cells)

- Severe swelling or deformation

- Leaking electrolyte

- Cells that won't hold charge

- Batteries that heat abnormally

- Any battery that has been on fire

Never:

- Throw in regular trash

- Puncture intentionally

- Incinerate

- Disassemble without proper equipment

- Place in recycling bin without preparation

My Safe Disposal Procedure:

- Complete Discharge:

- Use specialized battery discharger to 0V

- For damaged batteries, use salt water method if safe:

- 1/2 cup salt per gallon of water

- Submerge battery for 2+ weeks

- Verify 0V with multimeter

- Never discharge damaged batteries with normal chargers

- Terminal Isolation:

- Cover all terminals with non-conductive tape

- Secure balance leads

- Place in non-conductive container

- Proper Disposal Channels:

- Electronics retailers with battery recycling

- Hazardous waste collection facilities

- Battery recycling centers

- Manufacturer take-back programs

- Community hazardous waste events

For Severely Damaged Batteries:

- Double-bag in heavy plastic

- Place in fireproof container

- Label clearly as "Damaged Lithium Battery"

- Transport directly to hazardous waste facility

- Call ahead to confirm acceptance

I take battery disposal very seriously. For standard end-of-life batteries, I discharge them to 0V using a specialized discharge tool, then take them to a local electronics retailer with a battery recycling program. For damaged batteries, I use the salt water method to ensure complete discharge before disposal at a hazardous waste facility.

Conclusion

Proper battery storage, transport, and discharge procedures are fundamental aspects of responsible drone operation. By implementing the practices outlined in this guide, you can significantly extend battery life, reduce safety risks, and ensure compliance with regulations.

Remember that lithium batteries represent both a significant investment and a potential hazard. The time invested in proper handling procedures pays dividends through extended battery lifespan, improved performance, and most importantly, enhanced safety for you and those around you.

As battery technology continues to evolve, staying informed about best practices remains essential. However, the fundamental principles of proper storage voltage, appropriate containment, temperature management, and careful handling will remain relevant regardless of advances in battery chemistry.

By developing a systematic approach to battery management that includes proper storage, safe transport, and appropriate discharge procedures, you'll not only get the most from your drone batteries but also contribute to the overall safety and sustainability of the hobby and profession.

Comments ()